There have been certain times when carpet cleaners tell their clients that their carpet has to be cleaned a certain way, with a certain chemical, in order for it to look clean, fully dried, and not have any kind of terrible odors. This is because of what type of carpet fiber they own (olefin, polyester, nylon, etc.) and how the carpet was made. If not cleaned or treated in the correct way, it can be lead to difficult problems and unfortunate situations.

The following information in this article (as well as the others soon to follow) will give a brief but helpful explanation on the various types of manufactured carpets.

But why do I need to know this information? Well, as much as we would like to, we cannot be in multiple places at once, so this is more or less of what you would be told.

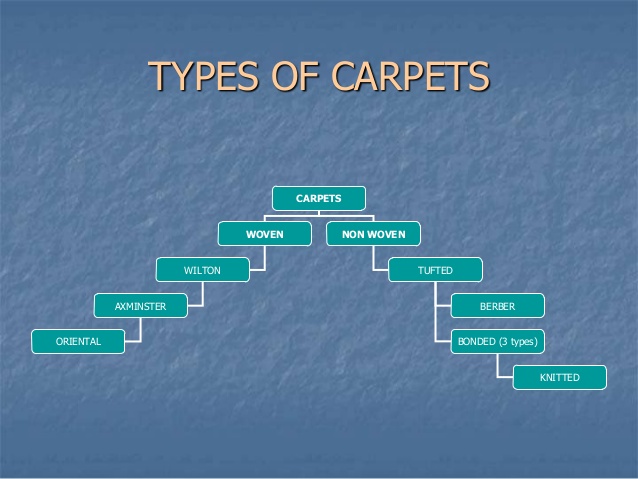

Woven Carpets

These carpets are usually the most expensive due to the relatively slow speed of the manufacturing process. These are very famous in India, Pakistan and Arabia.

The Components - Weaving is the process of using a loom to combine three sets of yarns to form the finished carpet. These yarn sets are: Warp, Weft, Pile, and Face

Warp Yarn - These run length wise in the carpet. Often cotton forms the warps. During weaving, they are placed under fairly severe tension, which is the reason cotton is used due to its strength. When these threads are wet during a cleaning process, they can shrink, and since cotton is stronger wet than dry, this shrinkage can be very pronounced.

Weft Yarn - These are yarns that run across the width of the carpet. They are also known as filler. These are normally jute, but polypropylene is becoming more popular. They run across the width in an over and under the warp pattern. They are subjected to very little strain during the weaving process, so shrinkage is possible, but much less likely.

The main problem with jute weft yarn is its tendancy to cause cellulosic browning, which is difficult to remove from wool face yarns.

Pile Yarns - shown on the surface and woven through the warp and weft. Traditionally, wool has been the yarn used in the pile, but over the years, we are seeing more synthetics used in woven carpets. Silk and other fibers are seen less often.

What is mostly causing the shrinkage is the construction of the carpet and the backing materials, not the pile yarn. Someone may see wool face yarn and assume it is a potential candidate for shrinkage. However, tufted wool carpet is no more likely to shrink than tufted nylon. Conversely, woven carpet with cotton or jute backing and synthetic pile yarn is just as likely to shrink as woven wool carpet.

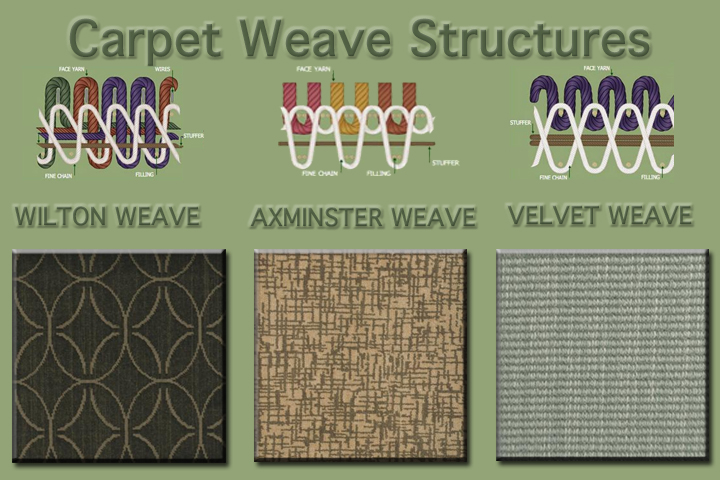

Basic Weaves

Wilton - created on jacquard loom, which use punch cards or computers to control the selection of yarns from the yarn reels to form the pattern. Most wilton looms work with a maximum of five colors. There a few looms capable of making patterns up to 8 colors. As one color at a time is being pulled through the pile, the others are buried beneath the surface. This results in additional strength and resiliency. And, consequently, longer life. Pile height is controlled by pile wires and can be either looped or cut, depending on the edge of the wire selected.

Axminster - Identification of Axminster carpets can easily be made by pairs of stiff, (usually jute) weft shots, which allow the carpet to be rolled in the lengthwise direction only. The back has a ribbed appearance and no secondary backing.

It's also woven on a very sophisticated loom, which draws pile yarns from large spools, each wound with a different color of yarn. These yarns have been preset in proper sequence and delivered at the weaving section of the loom at the exact moment necessary to produce a predetermined pattern in the carpet. The ends of the yarn are inserted between the warp threads in the loom.

Velvet - A simple loom that produces plush or velvet cut pile carpet. This is the least expensive and least durable of woven good.

So why would anyone use a woven carpet if it is so difficult to clean? The answer: it wears well and has great dimensional stability. With all of the components interwoven, it wears extremely well and won't delaminate under heavy traffic, service carts or other wheeled traffic, as tufted carpets tends to do. Woven carpets are used in high traffic areas of many fine hotels, casinos, etc.